Delta meets your total value proposition –

Precision, Consistency, OTD, PPM.

We have what you need:

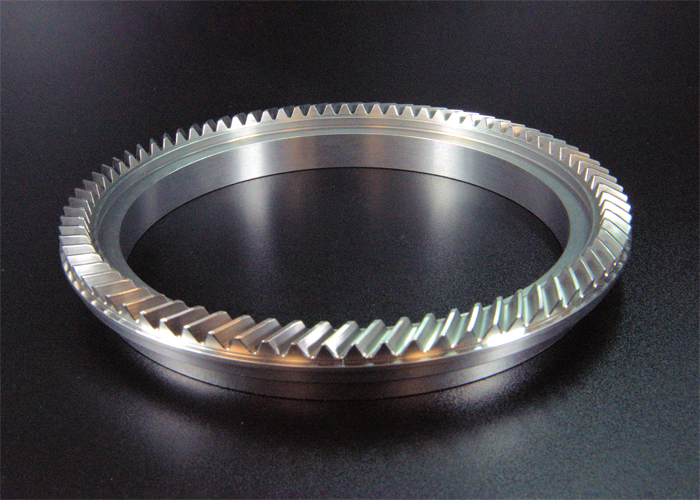

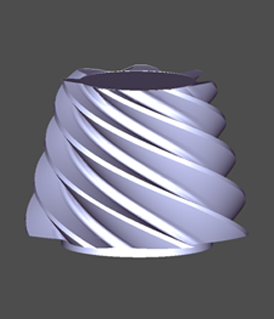

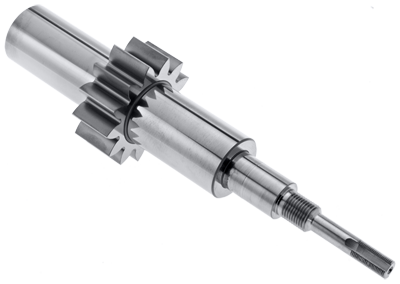

- Spiral Bevel Gears – Hypoid & Zerol

- The top manufacturing and methods engineering talent resides with Delta Gear today. Our engineering personnel have developed bevel gear manufacturing processes throughout the years for Turbine Engine customers such as: Rolls-Royce USA & UK, Hispano Suiza (Rolls-Royce and CFM Bevels), General Electric, Honda Jet, Pratt Whitney, Lockheed / Sikorsky, Honeywell, Liebherr Aerospace and Hamilton Sundstrand (UTAS).

Engine Bevel Gear development and production programs included: Trent, Leap, CFM-56 and PW1000 Pure Power.

Helicopter Drive System Bevels include: Blackhawk, CH53E & CH53K just to name a few.

These efforts included Development parts, Production parts including Bevel Master Gears. Our Engineering Team has extensive hands on experience with Welded Bevel Gears on the Leap Engine Inlet Gearbox program as well. We have highly skilled Bevel Gear Machinists, Process Engineers, Engineering Manager, Manufacturing Engineers and Inspectors who are experts at inspecting bevels with the latest electronic technology. Our Manufacturing leadership has significant experience manufacturing complex, flight safety, spiral bevel gears specifically for turbine engines, actuation and helicopter drive systems.

The Delta Gear name is newer to production spiral bevels, that’s true. However, more importantly the people we have here at Delta Gear today are some of the top talent in the gear industry in North America and are definitely not new to complex production Aerospace spiral (Hypoid & Zerol) bevels.

Our engineering and manufacturing resources are stronger today than ever and we continue to strengthen the bench on the program management side as well. When it comes to technical know-how on spiral bevels we are becoming the new industry leaders. Our customers tell us that.

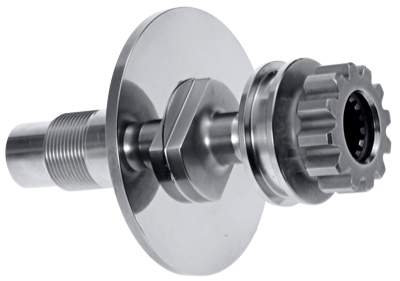

- Curvic Coupling

- Although they are not technically classified as gears, curvic couplings are produced on hypoid gear manufacturing equipment. Curvic couplings are used for joining two or more members to form a single operating unit and have high precision tolerances, requiring highly-specialized grinding techniques and expertise for extreme accuracy.

- Helical – Internal & External

- Herringbone (Double Helical)

- Spur – Internal & External

- Ring – Internal & External

- Hub Gear

- Compound Gear

- Pump Gear

- Starter Gear

- Accessory Gears

- Power Take Off Gears

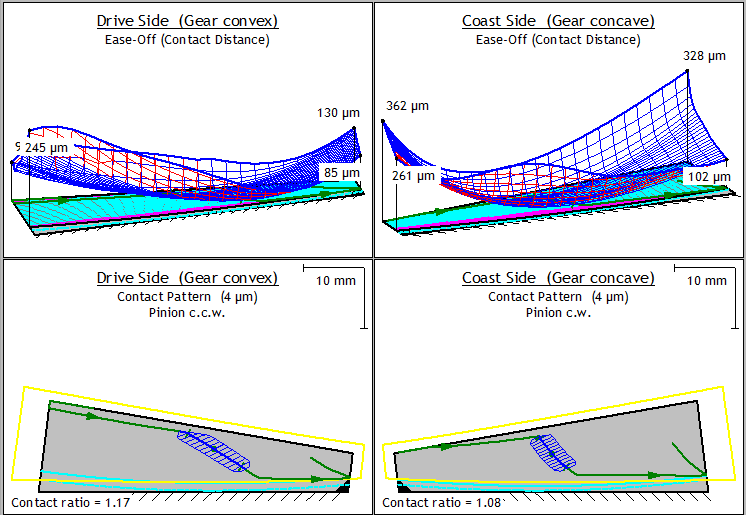

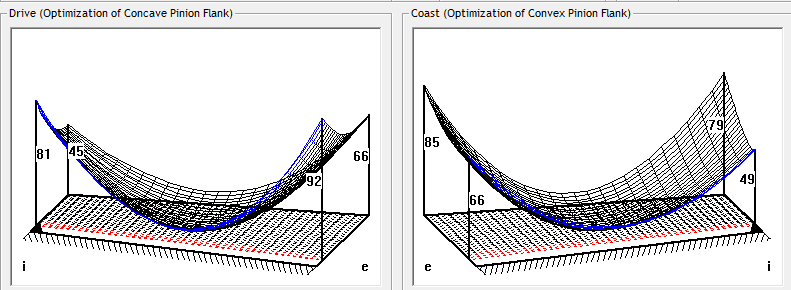

Klingelnberg G60 Spiral Bevel Gear Grinder